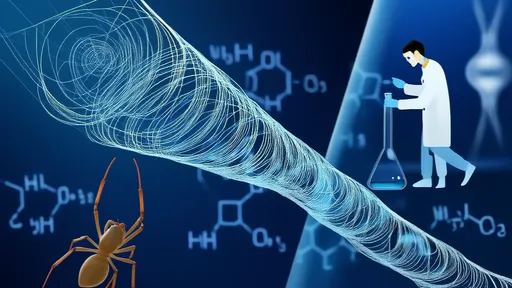

The natural world has long been a source of inspiration for scientists and engineers, but few materials have captured the imagination quite like spider silk. Known for its extraordinary strength and elasticity, spider silk has been studied for decades in the hope of replicating its properties for human use. Recent breakthroughs in biotechnology have brought us closer than ever to harnessing this wonder material, with synthetic versions now rivaling the tensile strength of high-grade steel while remaining five times tougher. This revolutionary material, often referred to as "bioderived steel" or simply "biosteel," promises to transform industries from medicine to aerospace.

What makes spider silk so remarkable is its unique molecular structure. Unlike steel, which relies on rigid atomic bonds for strength, spider silk derives its toughness from a combination of crystalline regions and elastic protein chains. When subjected to stress, these protein chains unfold and absorb energy, preventing the material from snapping under pressure. This molecular architecture allows spider silk to withstand impacts that would shatter or deform traditional metals. Researchers have spent years decoding these biological blueprints, and their efforts are finally yielding synthetic alternatives that mimic nature's design.

The production of biosteel represents a triumph of bioengineering. Rather than farming spiders—a notoriously difficult endeavor due to their cannibalistic tendencies—scientists have turned to genetic modification. By inserting spider silk genes into bacteria, yeast, and even goats, researchers have created organisms capable of producing silk proteins in large quantities. These proteins are then extracted and spun into fibers using specialized processes that replicate the natural spinning mechanism of spiders. The result is a material that retains the key mechanical properties of natural spider silk while being scalable for industrial applications.

One of the most promising aspects of biosteel is its environmental advantage over traditional steel production. The steel industry accounts for approximately 7% of global carbon emissions, requiring immense amounts of energy to mine and process iron ore. In contrast, biosteel production relies on renewable biological systems that operate at room temperature and pressure. The fermentation processes used to grow silk-producing microorganisms consume far less energy and generate minimal waste. As the world seeks sustainable alternatives to carbon-intensive materials, biosteel offers a compelling solution that aligns with circular economy principles.

Medical applications for biosteel are particularly exciting. The material's biocompatibility and gradual biodegradability make it ideal for surgical sutures, ligament repairs, and even artificial tendons. Unlike traditional synthetic fibers that may cause inflammation, spider silk-based materials integrate seamlessly with human tissue. Researchers are exploring its potential for nerve regeneration, where its conductive properties could guide the growth of damaged neurons. The material's strength-to-weight ratio also makes it suitable for lightweight casts and braces that provide support without restricting movement.

In the realm of personal protection, biosteel could revolutionize body armor design. Current bulletproof vests rely on layers of Kevlar or similar synthetic fibers that, while effective, add considerable bulk and weight. Biosteel's superior energy absorption capabilities could lead to thinner, more flexible armor that offers better protection with greater comfort. Military researchers are particularly interested in its potential to stop high-velocity projectiles while remaining breathable—a combination that has eluded conventional materials. The same properties make it attractive for protective gear in extreme sports and hazardous occupations.

The aerospace industry stands to benefit significantly from biosteel's unique characteristics. Aircraft manufacturers constantly seek materials that reduce weight without compromising strength. Biosteel's exceptional strength-to-weight ratio could lead to lighter airframes that improve fuel efficiency while maintaining structural integrity. Its vibration-damping properties might also reduce noise in cabin interiors. Some visionaries even speculate about its use in space elevators—theoretical structures that would transport payloads to orbit without rockets—where its tensile strength could theoretically support the enormous stresses involved.

Despite these exciting possibilities, challenges remain in bringing biosteel to mainstream adoption. Scaling up production while maintaining consistent quality has proven difficult, with variations in protein folding affecting the final material's properties. The spinning process, though improved, still lacks the precision of a spider's spinnerets. Cost remains another barrier; while prices have dropped significantly since the first synthetic spider silks were produced, biosteel still cannot compete with conventional steel on price alone for most applications. Researchers are working to optimize both the biological production systems and the mechanical spinning processes to address these limitations.

Ethical considerations also accompany this biotechnology revolution. The genetic modification of organisms to produce foreign proteins raises questions about containment and potential ecological impacts should modified organisms escape laboratory or production facilities. Patent disputes have already emerged over various spider silk genes and production methods, highlighting the commercial stakes involved. As with any disruptive technology, society will need to balance innovation with responsible oversight to ensure biosteel's development proceeds safely and equitably.

Looking ahead, the potential applications for biosteel continue to expand. Architects envision bridges with self-repairing biosteel cables that mimic how spiders maintain their webs. Automotive engineers imagine crash-absorbing biosteel components that protect passengers while reducing vehicle weight. Even the fashion industry has taken notice, with designers experimenting with biosteel fabrics that combine luxury with unparalleled durability. As production methods improve and costs decrease, we may see this remarkable material become as ubiquitous as plastics or aluminum are today.

The development of biosteel represents more than just another industrial material—it exemplifies a new paradigm in manufacturing that draws inspiration from nature's solutions. By understanding and replicating biological designs perfected over millions of years of evolution, scientists have created a material that outperforms human-engineered alternatives in multiple dimensions. As research continues and applications multiply, biosteel may well become one of the defining materials of the 21st century, proving that sometimes the most advanced technologies are those that nature has already invented.

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025

By /Jun 9, 2025